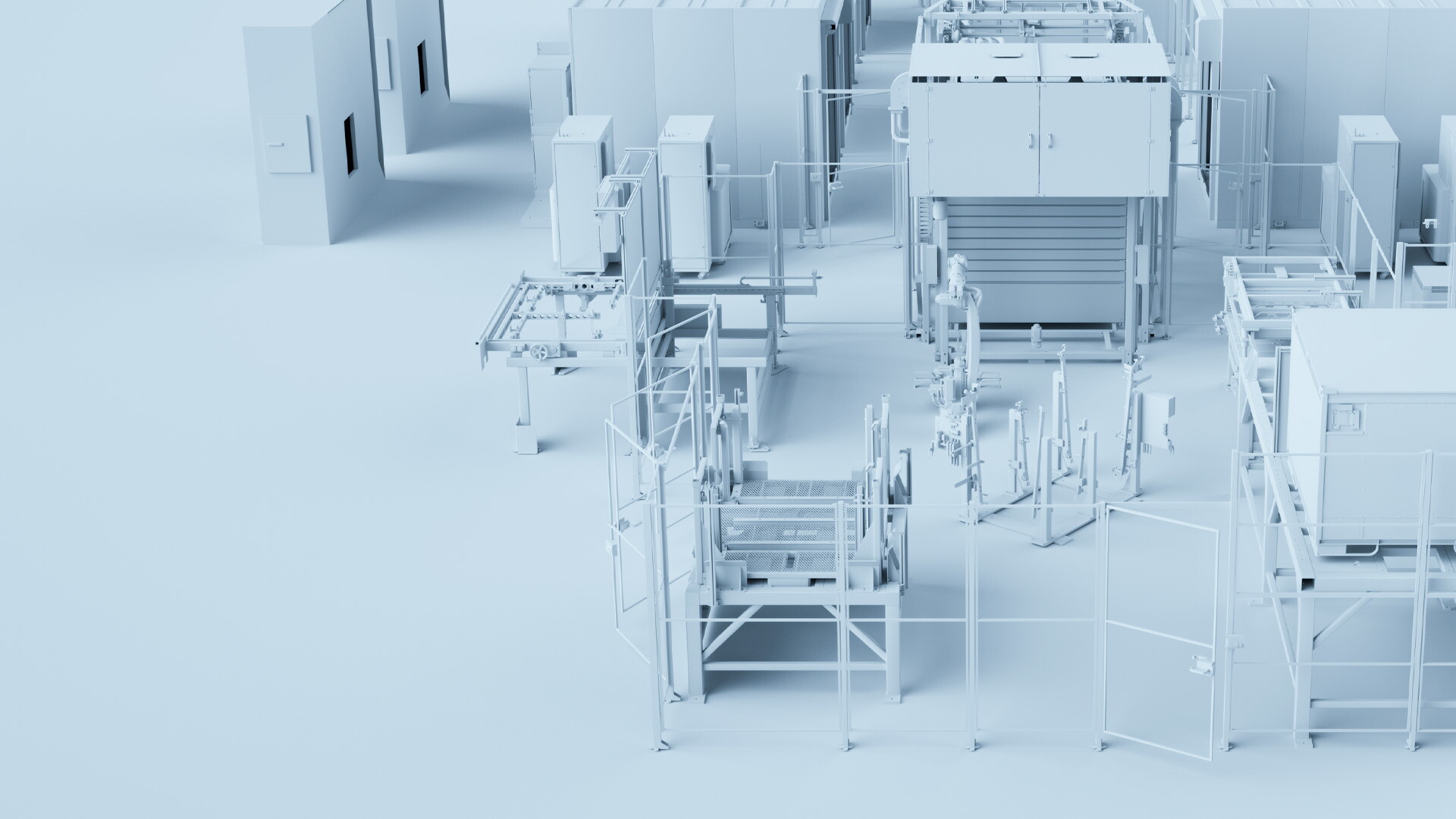

Our product range has a few core areas specializations. This has allowed us to optimize the systems, allowing our customers to achieve the highest possible cost-effectiveness for their production.

Due to the special requirements of our products, the in-house proportion of the systems is very high. This means that innovations, customer suggestions, and in-house experience are immediately incorporated into our systems. When it comes to purchased parts, we only use components from long-standing suppliers of the highest quality.

Additional

information