Laser robot

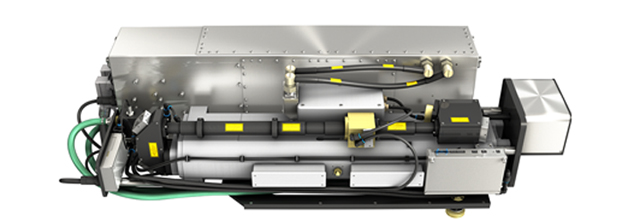

ROBOCUT A 300

Outstanding component accessibility // Reliable and economical // Laser power of 100 - 1000 W

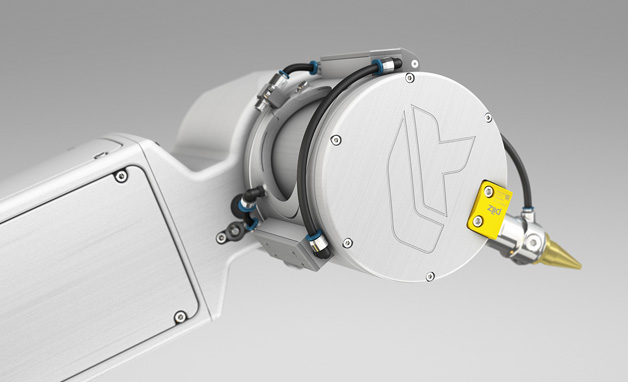

LASER-CUTTING NOZZLE

The extremely streamlined design of the laser-cutting nozzle

makes the components very accessible. The process gas supply

is provided through channels in the nozzle, which eliminates

external hoses. Depending on the task, we offer cutting nozzles

with a variety of focal lengths.

The optical cutting head has a removal slot to allow quick disassembly

for maintenance work.

LASER AND RF NETWORK COMPONENT

The CO2 lasers are based on a sealed-off-construction that allows the lasers to be operated for more than 15,000 hours without changing the gas. The integrated low-output diode laser makes it easier to calibrate the beam and is an enormous help for programming of the components.

The RT network component integrated into the robot offers significant advant-ages over conventional systems, since it completely eliminates the load on the RF cable. The entire RF network component can be switched out quickly and easily for servicing.

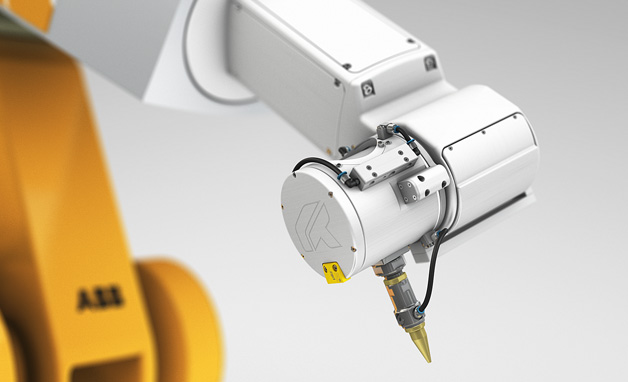

SCANNER

The integrated scanner (laser beam deflection through two extremely lightweight mirrors) covers a processing surface with a diameter of 150 mm when the robot is at rest. The robot universally positions the scanner unit at the components. This allows all kinds of contours to be cut and labeled with the greatest degree of pre- cision and speed. When cutting a circle, it can achieve a concentricity of +/- 0.02 mm.

DISTANCE SENSOR

The patent-pending distance sensor, which was specially developed for the area of

metal cutting, is manufactured jointly with the Precitec company. Precitec is a

well-known manufacturer and market leader in the area of distance sensors for laser-

cutting applications. This guarantees industrial standards and high quality.

Integrating the distance sensor into our laser robot creates a compact structure,

with a very short distance between the robot’s center of rotation and the

processing point on the component. This allows for outstanding component

accessibility, very good path repeatability and fast reorientation.